Brewery Wastewater Recycling & Reuse: Sustainable Solutions for Compliance, Cost Savings, and Environmental Stewardship

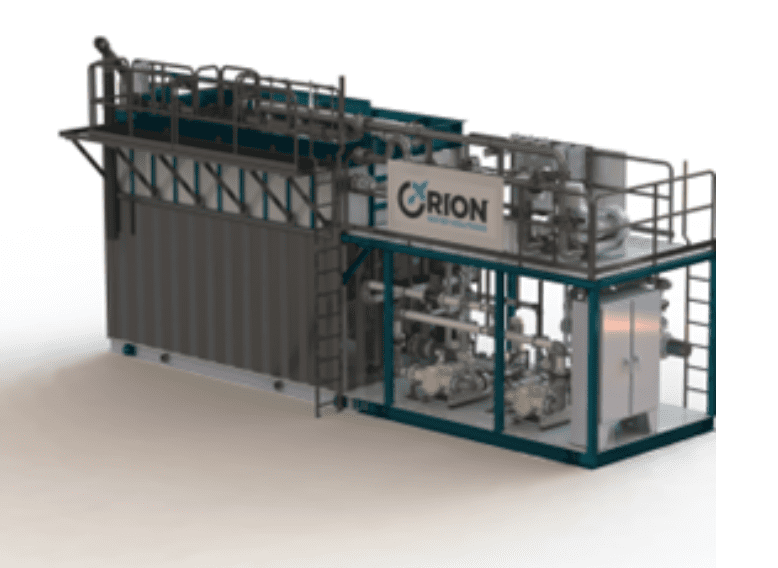

As the craft beer industry continues to surge in popularity, breweries face increasing pressure to manage their wastewater sustainably. The production of beer inherently involves large volumes of water, which must be treated before discharge to comply with environmental regulations, reduce surcharges, and minimize ecological impact. At Orion Water Solutions, we understand the unique challenges that breweries face and have developed tailored, advanced treatment systems that not only ensure regulatory compliance but also boost cost savings, resource recovery, and overall profitability.

The Challenges of Brewery Wastewater

Breweries generate wastewater with high levels of Biological Oxygen Demand (BOD), nutrients, and suspended solids. These parameters are closely monitored by regulatory agencies, and failure to comply can lead to hefty fines, surcharges, and damage to a brewery’s reputation. Increasingly stringent regulations demand that breweries adopt effective, reliable wastewater treatment solutions that can consistently meet or exceed discharge limits. Beyond regulatory concerns, inefficient wastewater management increases operating expenses. Surcharges on excess BOD or nutrient discharges, coupled with rising freshwater costs, strain margins and undermine long-term growth. Amid these challenges, breweries that prioritize wastewater reuse and recycling not only maintain compliance but also enhance their brand’s commitment to sustainability.

Orion’s Advanced Wastewater Treatment

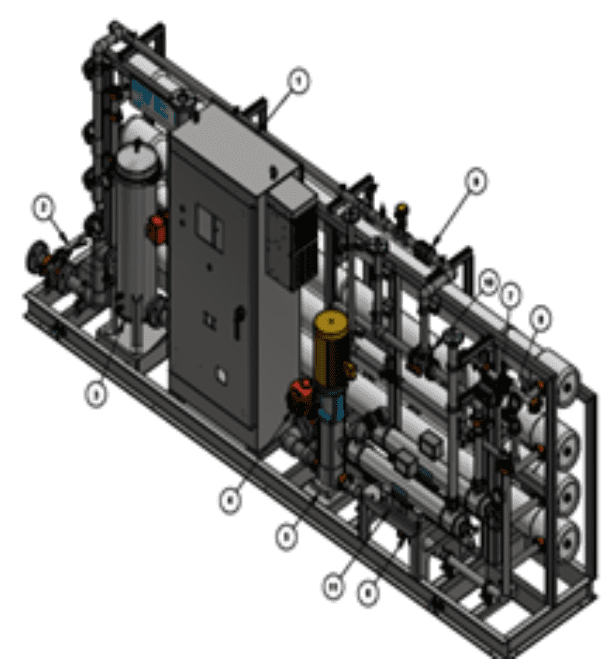

Orion offers comprehensive wastewater recycling and treatment solutions designed specifically for breweries. Our systems integrate advanced biological treatment with membrane filtration techniques like membrane bioreactors (MBR), reverse osmosis (RO) technology, and also advanced disinfection methods to achieve consistently high-quality effluent suitable for non-potable reuse applications.

- Membrane Bioreactors (MBR):

MBR systems combine biological treatment with ultrafiltration membranes to effectively remove suspended solids, bacteria, and high levels of organic matter. The membranes act as a physical barrier, ensuring superior effluent quality and stable performance even with fluctuating load conditions. By providing exceptional BOD removal, MBR systems help breweries remain well within regulatory discharge limits.

2. Reverse Osmosis (RO):

RO is a pressure-driven process that removes dissolved salts, minerals, and contaminants to achieve a high level of purity. By incorporating RO into our treatment train, Orion can help breweries reuse their treated wastewater for various non-potable applications, such as cooling processes, equipment rinsing, and floor washing. This closed-loop approach reduces the overall demand for fresh water and supports long-term resource conservation.

3. Disinfection:

Post-treatment disinfection—whether through ultraviolet (UV) light, ozone, or chemical agents—further enhances water quality by eliminating pathogenic microorganisms. Ensuring safe, pathogen-free water is essential when reusing treated effluent and upholding stringent health and safety standards.

Sustainability and Compliance: A Win-Win Approach

The cornerstone of Orion’s solutions lies in meeting the strict discharge regulations that control effluent BOD and nutrient levels. By tailoring treatment trains to the unique needs of each brewery, we ensure the final effluent not only meets but often surpasses local and federal standards. Compliance with these limits reduces or eliminates wastewater surcharges, improves brand reputation, and provides a competitive advantage.

Moreover, by embracing wastewater recycling, breweries can dramatically decrease the volume of water required from external sources. This reduction in freshwater demand protects local aquifers, rivers, and lakes, and helps breweries align with global sustainability goals. For more guidance on best practices and standards, the U.S. Environmental Protection Agency (EPA) offers valuable resources and insights into water quality and effluent.

Lowering the Carbon Footprint and Energy Costs

Sustainable wastewater management is not just about meeting regulations or saving money; it’s also a powerful way to reduce a brewery’s carbon footprint. By minimizing the need for fresh water trucking, decreasing effluent volumes, and reducing energy-intensive disposal methods, breweries can significantly lower greenhouse gas emissions associated with water procurement and wastewater hauling. These efficiency gains translate into both environmental benefits and operational cost savings.

management.

Enhanced Profitability and Resource Recovery

What was once considered a liability—wastewater—is now a resource that can be recovered and reused. Reclaiming water for non-potable applications reduces the brewery’s reliance on costly fresh water, stabilizing supply even during droughts or peak demand periods. Over time, this approach leads to substantial savings, as the brewery invests less in incoming water and avoids penalties for discharging non-compliant effluent.

Additionally, by investing in Orion’s state-of-the-art treatment systems, breweries can potentially recover other valuable byproducts. Nutrients extracted from wastewater can sometimes be repurposed as fertilizers, turning a cost center into a revenue opportunity. Although these applications vary depending on local regulations and operational scale, the potential for resource recovery further improves return on investment.

Integrating Solutions Across the Food and Beverage Sector

Brewery wastewater challenges share similarities with those faced by other segments of the food and beverage industry. Orion’s experience extends to related sectors, including dairy wastewater recycling and reuse and tea and juice wastewater management. Our cross-industry expertise allows us to continuously refine our technologies, ensuring that breweries benefit from the most up-to-date, proven solutions on the market.

Long-Term Support and Collaborative Partnerships

At Orion, we believe that effective wastewater management is an ongoing process rather than a one-time fix. Our team of engineers, technicians, and field operators work closely with breweries to ensure seamless installation, commissioning, and integration of our systems. Beyond implementation, we offer remote monitoring, process optimization, and regular maintenance services to keep systems operating at peak performance.

Our commitment to collaboration extends to helping breweries navigate permitting, understand evolving regulations, and optimize their wastewater management strategies. By forging long-term partnerships, Orion stands ready to support breweries as they grow, evolve, and adapt to new market conditions and environmental requirements.

A Responsible Approach to Brewing’s Future

In a marketplace increasingly defined by environmental responsibility and operational efficiency, breweries that invest in advanced wastewater recycling and reuse solutions not only thrive today but also future-proof their operations. Aligning with Orion Water Solutions ensures breweries meet rigorous compliance standards, reduce costs, bolster brand reputation, and uphold their commitment to sustainability.

For more detailed information or to explore how our specialized treatment systems can support your brewery’s unique needs, Contact Us today. Our experts are ready to answer your questions, share industry insights, and help you transform wastewater management into a strategic advantage—protecting both the environment and your bottom line.