Manufacturing Water Treatment Systems: Enhancing Efficiency, Compliance, and Sustainability

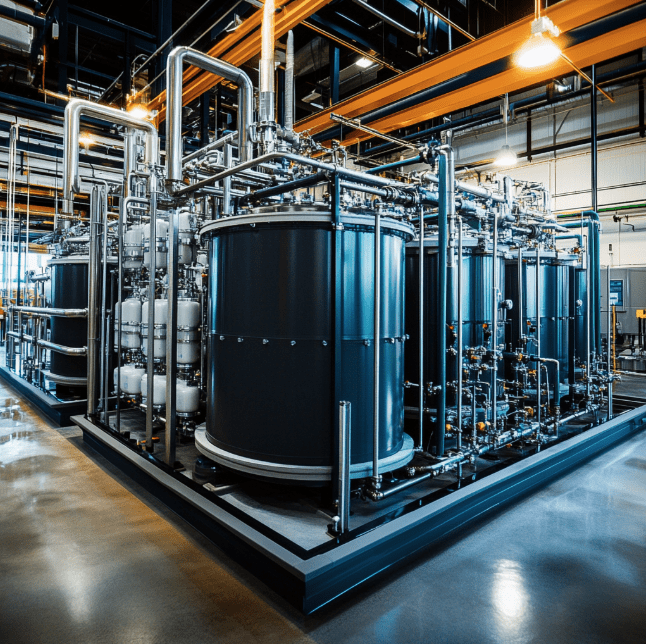

In today’s fast-paced industrial environment, manufacturers face unprecedented challenges—rising production costs, rigorous environmental regulations, complex wastewater streams, and increasing pressure to reduce their carbon footprints. A strategic approach to water and wastewater management is no longer an option; it’s a competitive necessity. At Orion Water Solutions, we provide manufacturing clients with innovative treatment systems designed to optimize water usage, ensure regulatory compliance, and advance sustainable practices.

The Imperative of Advanced Water Treatment in Manufacturing

Industrial manufacturing processes often rely heavily on water for cleaning, cooling, processing, and other critical functions. As a result, wastewater discharge carries a variety of contaminants—from oils, greases, and heavy metals to organic compounds and suspended solids. Without proper treatment, these contaminants pose environmental hazards, incur costly surcharges, and risk violating local, state, and federal regulations.

Modern consumers and investors increasingly demand that manufacturers embrace sustainable, responsible practices. Implementing comprehensive water treatment systems allows facilities to reduce their freshwater consumption, minimize disposal volumes, and comply with stringent environmental standards. By turning a compliance challenge into an opportunity, manufacturers can lower costs, enhance community relationships, and strengthen their brand reputation.

Customized Treatment Solutions for Diverse Manufacturing Sectors

No two manufacturing facilities are alike. Variations in processes, raw materials, and effluent characteristics call for tailored solutions that address the unique demands of each operation. Orion’s team of engineers and technicians thoroughly analyze your wastewater profile and production requirements to recommend the most effective treatment train.

Common technologies integrated into our manufacturing-focused solutions include:

- Dissolved Air Flotation (DAF):

DAF units remove oils, greases, and suspended solids efficiently, making them ideal for pre-treating wastewater from industries such as automotive parts manufacturing, electronics assembly, and metal finishing. - Membrane Bioreactors (MBR) and Moving Bed Biofilm Reactors (MBBR):

By combining biological treatment with advanced filtration, MBR and MBBR systems effectively break down complex organic compounds and stabilize effluent quality. These technologies are suitable for a broad range of manufacturing applications, from food and beverage production to chemical synthesis. - Reverse Osmosis (RO) and Ultrafiltration (UF):

RO and UF membranes remove dissolved salts, heavy metals, and fine particulates, producing high-quality effluent that can often be reused for non-potable applications. This approach can dramatically reduce freshwater demand and disposal costs, supporting both environmental goals and regulatory compliance. - Oxidation and Advanced Oxidation Processes (AOPs):

Some industrial contaminants resist conventional treatments. Oxidation and AOPs, such as ozone or UV/H₂O₂, target these persistent pollutants, breaking them down into simpler, less harmful compounds. These solutions are particularly valuable when dealing with emerging contaminants, complex chemical byproducts, or stringent effluent standards.

Integration with Other Industry Solutions

Orion’s expertise extends beyond manufacturing wastewater. We serve multiple sectors, including upstream oil and gas, food and beverage, dairy processing, and municipal systems. Our cross-industry experience enables us to draw on best practices, proven technologies, and innovative solutions that enhance the efficiency, reliability, and scalability of your manufacturing water treatment processes.

Regulatory Compliance Made Simple

Compliance with environmental regulations is a cornerstone of operational integrity for manufacturers. Laws governing wastewater discharges are becoming more stringent, with frequent updates that require ongoing adaptation. Orion stays ahead of regulatory trends, ensuring that our treatment systems not only meet current standards but are also designed with the flexibility to adapt to future changes.

From controlling nutrient levels and reducing heavy metals to meeting tight discharge limits on BOD, COD, and suspended solids, our solutions align with the latest guidelines. To stay informed about broader environmental regulations and best practices, consider consulting resources like the U.S. Environmental Protection Agency (EPA), which provides valuable insights on water quality standards, pollutant management, and emerging contaminants.

Streamlined Operations and Cost Savings

Effective water treatment does more than protect the environment and ensure compliance—it also delivers tangible economic benefits. By removing contaminants at the source and optimizing reuse opportunities, manufacturers can:- Reduce Disposal Costs: Lowering the volume of wastewater sent to disposal wells or landfills cuts down on transportation, energy consumption, and related fees.

- Minimize Surcharges: Many municipalities charge extra fees for wastewater that exceeds certain pollutant thresholds. Consistent and reliable treatment helps facilities avoid these surcharges.

- Lower Freshwater Demand: Reusing treated water reduces reliance on scarce freshwater resources and can stabilize costs in regions where water availability or quality fluctuates.

- Enhance Equipment Longevity: Improved water quality can extend the lifespan of production equipment, piping, and downstream infrastructure by preventing corrosion, scaling, and fouling.

Championing Sustainability and Corporate Responsibility

With consumers, investors, and communities placing more weight on corporate social responsibility, sustainable water management is a strategic advantage. By integrating advanced treatment systems, manufacturers demonstrate their commitment to environmental stewardship, resource conservation, and responsible growth.

Reduced water footprints and minimized environmental impacts help companies differentiate themselves in competitive markets. Customers increasingly reward brands that prioritize sustainability, and regulatory bodies may offer incentives or recognize companies that exceed compliance requirements. A proactive, environmentally responsible water management strategy can enhance stakeholder trust, attract talent, and solidify a manufacturer’s reputation as a forward-thinking industry leader.

Ongoing Support, Maintenance, and Optimization

Installing a treatment system is only part of the journey. Orion provides comprehensive support services to ensure your systems continue operating at peak efficiency. This includes remote monitoring, routine maintenance, process optimization, and operator training. As your production processes evolve, we stand ready to adjust treatment parameters, implement new technologies, or integrate additional stages to meet changing needs.

Building a Sustainable Future Together

As manufacturing sectors become more complex, efficient water and wastewater treatment is critical for long-term resilience and success. Orion Water Solutions delivers holistic, high-performance systems that address pressing environmental challenges while offering tangible financial benefits and fostering regulatory compliance.

We invite you to learn more about how our manufacturing treatment systems can enhance your operations, reduce costs, and safeguard the environment. Visit our About Us page or Contact Us to discuss your facility’s specific requirements. Together, we can forge a sustainable future where manufacturing excellence and environmental responsibility go hand in hand.